Driving Manufacturing and Production Efficiencies

“How do we get more production output through our machines, increase automation and reduce costs, errors and material wastage?”

This is a question you may be asking yourself as you look for innovative ways to increase production and operational efficiencies without compromising on quality, increasing staff or machining costs.

If you have a design team with all the latest efficient 3D modelling tools, why is there a bottle neck of work in production? Even if you don’t have a design team, why does it take so long to manually programme milling and turning machines which contribute to a reduction in production capacity? Maybe due to market skill shortages you just do not have enough highly skilled machine operators to get the best from your significant equipment investment.

You may also be asking why your machines are only running during “lights on” hours? Do machine operators not have the confidence in the programming to leave machines running throughout the night without error, or is there fear of clashes that will lead to expensive cutting tool breakages?

There are many root contributor causes to the problem, but there is one core solution to many of these issues – implement the right Computer Aided Manufacturing (CAM) software to maximise production, reduce material costs and improve the productivity of your CNC machine tools.

So, here begins your challenge. Type “CAM software” into your favourite search engine and be presented with numerous options from free software to eye wateringly expensive high-end options. If this is not daunting enough, open a feature comparison matrix and add to your confusion.

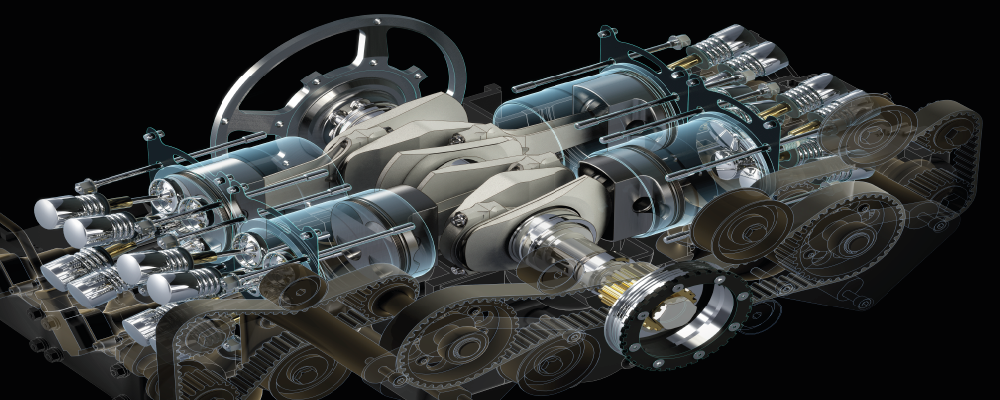

You could, however, take a different approach to the problem and tackle the issue from a business perspective and allow the Cadline CAM  team to assess your requirements and understand your environment, equipment and quality of production. As a result, you will be presented with only suitable options to solve your specific production issues. You will be introduced to CAM technologies from Autodesk that can deliver market leading precision manufacturing solutions with 3 – 5 axis capabilities. Technologies that are compatible with most machine manufacturers which will help you improve productivity, automate machine coding, protect your intellectual property, automate toolpath simulations and reduce costs.

team to assess your requirements and understand your environment, equipment and quality of production. As a result, you will be presented with only suitable options to solve your specific production issues. You will be introduced to CAM technologies from Autodesk that can deliver market leading precision manufacturing solutions with 3 – 5 axis capabilities. Technologies that are compatible with most machine manufacturers which will help you improve productivity, automate machine coding, protect your intellectual property, automate toolpath simulations and reduce costs.

Wouldn’t it make a difference to your business if you could make your least frequent machine operator as good as your most frequent machine operator and improve production outcomes across your machines during lights on and lights off hours?

Today, all those outcomes are possible and highly achievable, you just need to find the right partner and CAM software tools to make it a reality.

To read more about how Cadline can help you click here https://services.cadline.co.uk/cam/